CNCSPECTRAL DETECTION

The working principle of the spectrometer

A spectrometer is an advanced inspection tool that uses optics, electronics and computer technology for analysis. Its working principle is to convert the spectral information radiated by the substance into an electrical signal, which is then processed and analyzed by a computer. Spectrometers can detect the content and proportion of all elements in a material within a certain band range.

The principle of spectrometer detection of stainless steel content

In the composition analysis of stainless steel, the composition content can be determined by measuring the characteristic spectrum of its radiation. When the sample is heated, it produces a specific wavelength of light radiation, which changes depending on the chemical elements in the sample. By analyzing the characteristic spectrum generated by the stainless steel sample, the component content can be accurately measured, avoiding the chemical reaction and treatment process in the traditional method, and improving the accuracy and efficiency of the detection.

The advantages of stainless steel composition detection

Compared with traditional chemical analysis methods, spectrometer detection of stainless steel composition has the following advantages:

1. Fast and accurate: no need to use chemical reagents, reduce the processing and analysis time, and effectively improve the speed and accuracy of detection.

2. High reliability: The test results of the spectrometer are stable and reliable, and will not be interfered by impurities and colors.

3. Good repeatability: Different operators use the same spectrometer for testing, and the results have good repeatability.

Conclusion

Spectrometer is an efficient and accurate tool for material composition detection, which is more and more widely used in stainless steel products industry. The spectrometer does not need to use chemical reagents to detect the content of stainless steel components, and has the advantages of fast, accurate, reliable and good repeatability, which greatly improves the detection efficiency and accuracy.

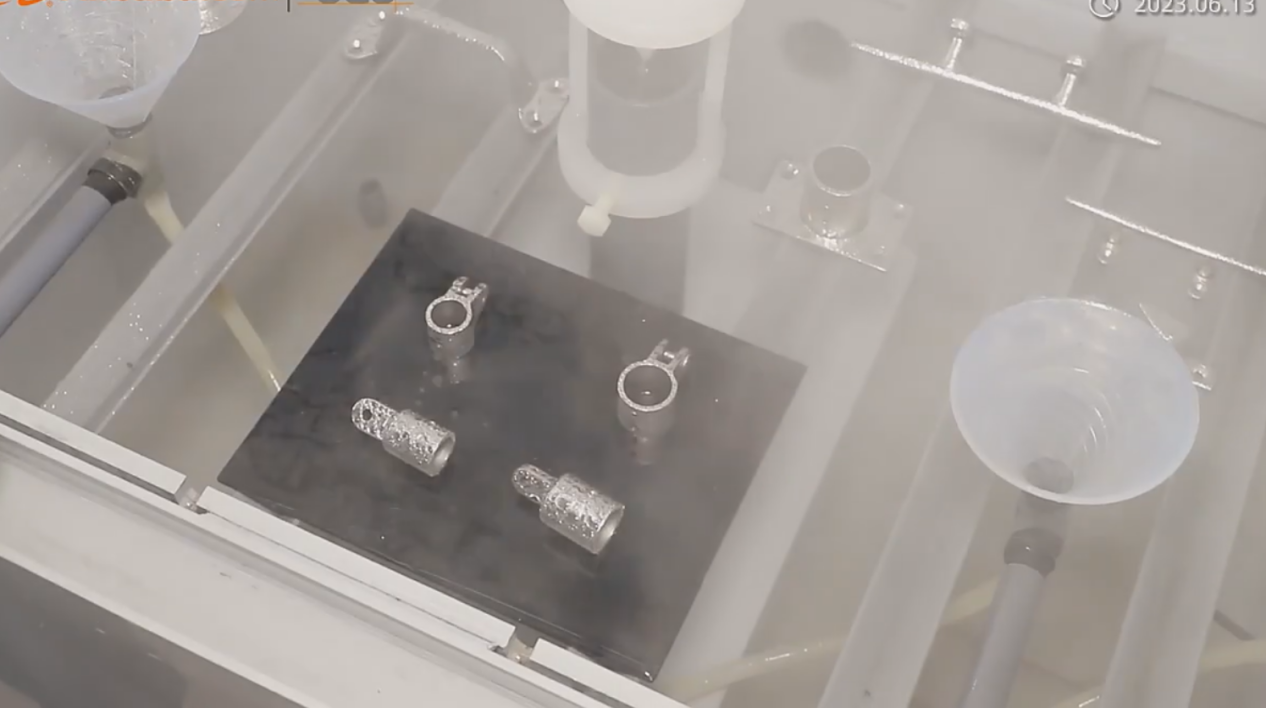

SALT SPRAY TESTING

Salt spray test is a kind of environmental test which mainly uses artificial simulated salt spray environmental conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials. It is divided into two categories, one is the natural environmental exposure test, the other is the artificial accelerated simulated salt spray environmental test.

Artificial simulated salt spray environmental test is to use a test equipment with a certain volume space - salt spray test chamber, in its volume space with artificial methods to create a salt spray environment to assess the quality of the product's salt spray corrosion resistance.